MOV is the key element of surge arrester. MOVs are made from high-quality metal oxide materials and have been designed to meet international quality standards. The product is specifically designed to provide protection from transient voltage surges that could cause damage to electronic devices and appliances.

complex structure of micro varistors consisting of Zinc oxide grains and surrounding high-resistance grain boundary layers, connected in series and parallel. Therefore, if the size of the Zinc oxide grains is the same, the varistor voltage is proportional to the thickness and the surge withstand capability is proportional to the cross-section area of the MOV

Compared to ordinary resistive elements, MOVs have a very large non-linear voltage-current characteristic, so they act as insulators in areas where the applied voltage is small, and as conductors in areas where the voltage is large, such as in lightning surges. This makes it possible to safely protect equipment from lightning surges.

Product name: metal oxide varistor resistor D32*20mm jinniu electric

Type: varistor D32*H20mm

The MOVs used in surge arresters and surge protective devices (SPD) are manufactured under strict quality control and have excellent non-ohmic properties, high surge withstand capability and longer service life.

Excellent non-ohmic propertyWhen an excessive surge is applied to a MOV, the terminal voltage of the MOV is kept as low as possible to protect electronic equipment and power facilities. High surge withstand capabilityUniformly current flow in an MOV due to high homogeneity of daily improved ZnO ceramics and high collaring materials having high insulation are realized. Long service lifeHigh reliability under the condition that system voltage is constantly applied. Wide range of products A wide range of AC and DC products, from low to high voltage, are available to meet a wide range of needs. Our MOVs satisfy international standards related to surge arresters, SPDs and MOVs(IEC, IEEE, UL etc..)

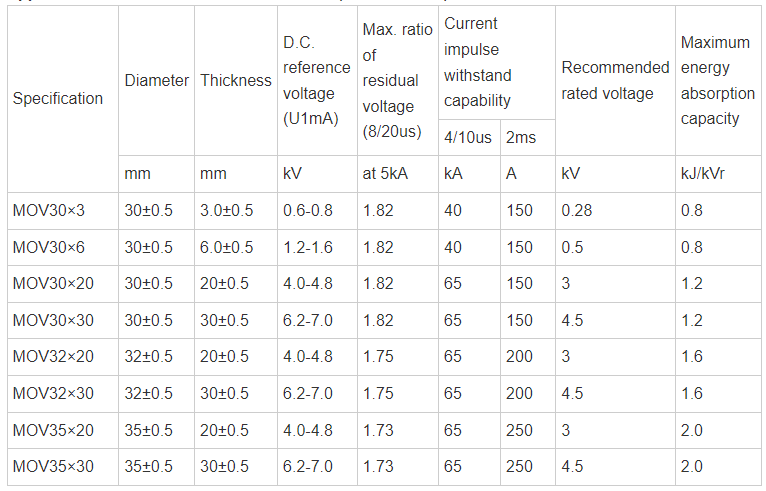

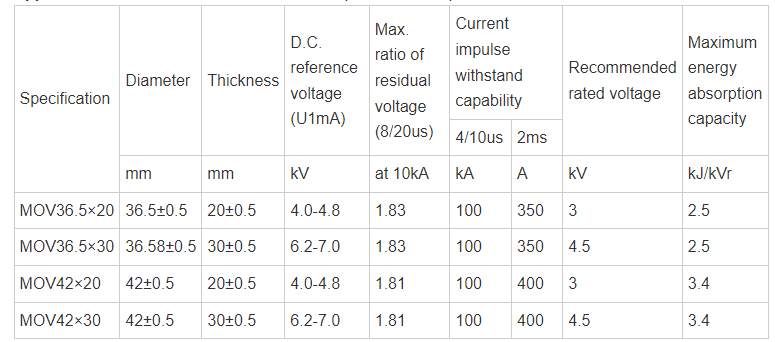

Specifications:

- Used for Arrester Classification DM (IEC Standard)

2) Used for Arrester Classification DH (IEC Standard)

Zinc Oxide discs, the prime elements for gapless surge arresters, incorporate the latest developments in metal oxide technologies and meet the stringent requirements of the relevant International standards, IEC 99-4, ANSI C62-11 and IS-3070 (Pt.3)1993 standards..

The metal oxide discs (MOD) are composed of a specially formulated compound of zinc oxide and proportionate amount of other selected metal oxides, a composition which has been arrived at through years of Research and Development. These ingredients are mixed in a powdered form, pressed to form a disc, and fired at high temperatures, resulting in a dense polycrystalline ceramic. The basic molecular structure is a matrix of highly conductive zinc oxide grains, surrounded by resistive intergranular layers of metal oxide elements. Under electrical stress, the inter-granular layers conduct, resulting in a highly non-linear characteristic. We have two type discs, one is zinc oxide discs, another is sic discs. You can custom them according to your requirement.

Zinc oxide discs in the Surge Arresters maintain a stable characteristic. Accelerated ageing tests show that arrester losses will not increase during an arrester’s service elife when exposed to a continuous steady state voltage. Stable Zinc Oxide Disc characteristics enable the Surge Arresters to maintain their low protective characteristics. As a result, equipment protection is never compromised. Factory tests are performed on each disc. Stability tests are conducted on each manufacturing lot to verify that the disc formulation and production processes are optimized. Every disc is submitted to an impulse current of 10 kA, 8/20 microseconds to measure its discharge voltage. A disc strength test, consisting of multiple transmission line impulse is performed to ensure the disc has full energy capability. Resistive power loss is measured at maximum continuous operating voltage and visual inspection of the discs completed the routine tests, Our products have all type test report, our surge arresters have the KEMA test report.

Changsha Rich’s range of ZnO discs, manufactured in different diameter and height combinations, meet the specific requirements of Distribution Class and Station Class-I to Class-IV of lightning Arrester.