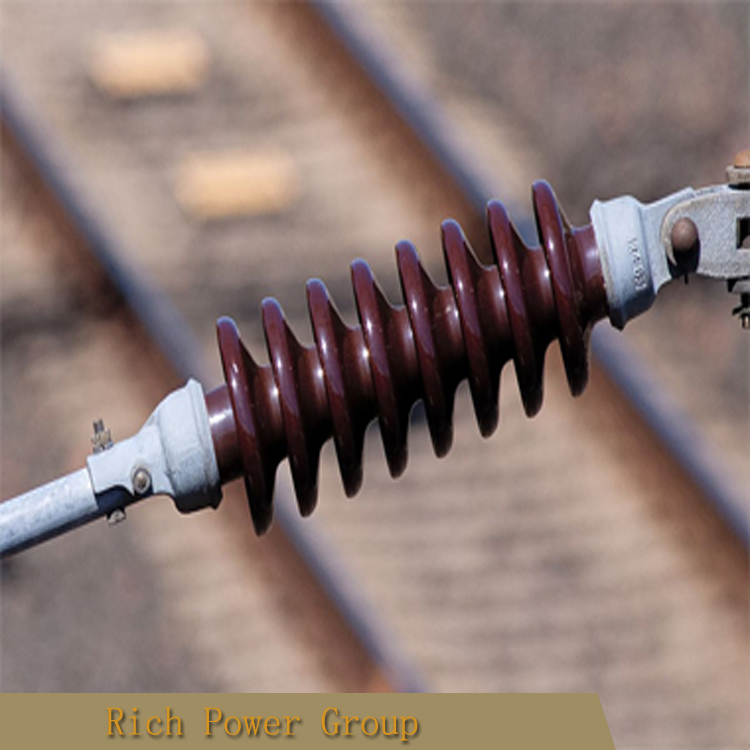

A reliable Rail network requires reliable insulators at its heart and although many new designs have been added to our ever expanding range over the years, the formulation has never changed and our reliable service history continues to be one of our greatest assets. porcelain long rod insulators have been well proven right around the World from desert conditions of Africa to the iced expanses of Canada and has also been used by many electricity utilities .

Porcelain long rod insulators are of solid core type “A” construction and are absolutely puncture-proof. These insulators are designed to provide flexible support same time ensuring that the tensile load requirements in service are met. The long rod insulators are subjected to static and dynamic loads including wind load, ice load, conductor galloping, short circuit forces etc. , and are designed to withstand such loads constantly and continuously for decades.

The insulators are made of high-quality Aluminous porcelain meeting the requirements of C130 in accordance with the IEC: 60672. Apart from the visual and dimensional checks, the long rod insulator shells are subjected to ultrasonic tests prior to assembly. Precision machines are used to cut and grind the end faces to achieve the required surface finish and chamfer of the ends.

Railway Insulator Applications:

Railway insulators have a very high resistivity as well as a low conductivity. Their atoms possess tight bound electrons which don’t actually move across the material. Since the electrons are always static as well as not roaming freely, the current can’t pass through it at all.

Railway Insulator Features:

- Explosion-proof for maximum safety

- Leakage current control through hydrophobicity

- Excellent insulation for reduced creepage

- Flashover resistance

- Outstanding seismic performance for safety and reliability

The products are suitable for electric-railway of complex operation conditions, can effectively prevent flash accidents and decrease the times of clear and maintenance, because of small volume, and when in the tunnel is clear products of glass insulator cannot instead of it. Polymer type is also produced.

Specifications and Types:

Rate Voltage:33kV-1200kV

Mechanical load: 45kN-420kN

Creepage distance: 12mm/kV – 35mm/kV

Standard: IEC61109

Application of Porcelain long rod insulators:

-Electric railway of complex operation conditions

-Use in industry-specific solutions

-Device and plant construction, e.g. switchgear, for busbars and disconnect switches

-Platform support for capacitor banks